Dissolvable Frac Plugs

Extended Reach Frac Plugs

Composite Frac Plugs

Bridge Plugs

Dissolvable Frac Plugs

Extended Reach Frac Plugs

Composite Frac Plugs

RECEDÓ™ FRAC PLUG SERIES

Optimized Performance. Tailored Solutions. Reliable Execution.

Stage isolation you can trust — Frontier’s frac plug lineup, led by the RecedóТМ series, is engineered to perform under pressure. From composite to dissolvable hybrids (coming soon), every plug is built to minimize debris, drill out clean, and maintain zonal isolation through extreme pressure cycles. Whether you need short-length tools, high-temp designs, or an extended-range solution like the RecedóТМ Twister, our portfolio delivers real-world reliability stage after stage. Field-proven isolation with next-generation performance — RecedóТМ is the standard, not the exception.

Recedó™ Dissolvable Frac Plugs

Built to disappear, engineered to deliver — RecedóТМ dissolvable plugs are customized to the well, not pulled from a shelf. Each plug is tailored to the casing ID, fluid chemistry, and temperature profile of your wellbore, ensuring predictable breakdown and uncompromising isolation. Our metal-to-metal sealing options, degradable rubber backup systems, and extended-range configurations give operators the ability to frac hard and transition fast — without the need for post-job intervention.

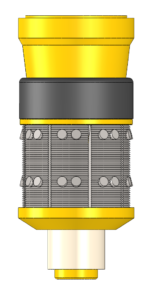

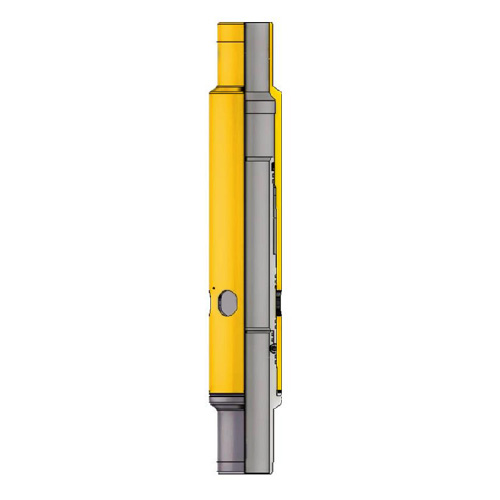

Lightning™ Dissolvable Frac Plug

- Metal-to-metal seal

- Rapid degradation

- Field-proven

The Recedó Lightning™ Dissolvable frac plug represents a significant advancement in frac technology, specifically designed to optimize performance while minimizing post-operation residue. Featuring a thin, minimal sealing element, the Lightning™ plug reduces the volume of rubber left behind after frac operations, addressing a common concern in the industry regarding cleanout and wellbore integrity. This innovative approach not only enhances the efficiency of post-fracturing processes but also contributes to a more environmentally friendly operation.

Built on the same robust platform as our Recedó Thunder™ Dissolvable frac plug, the Lightning™ offers the same impressive holding capability of up to 10,000 psi, ensuring that it can withstand the demanding conditions often encountered during hydraulic fracturing. Despite its streamlined design, the Lightning™ plug does not compromise on performance, making it a reliable choice for operators looking to maximize their frac efforts.

One of the key features of the Recedó Lightning™ plug is its high degree of customizability. Recognizing that every well and application presents unique challenges, each plug can be tailored to meet specific requirements, whether those involve varying pressure scenarios, different fluid types, or distinct wellbore characteristics. This level of versatility allows operators to optimize their frac operations effectively, ensuring the best possible outcomes even in the face of complex field conditions.

Furthermore, the design of the Lightning™ plug facilitates quick transitions during operations, allowing for efficient deployment and retrieval. Operators can easily adapt their strategies based on real-time data, making the Lightning™ an excellent choice for dynamic and fast-paced environments.

In summary, the Recedó Lightning™ Dissolvable frac plug combines innovative design with high performance and customizability, making it an essential tool for operators seeking to enhance their hydraulic fracturing operations. With its focus on reducing leftover materials and maintaining exceptional sealing capabilities, the Lightning™ plug offers a practical and effective solution to modern frac challenges.

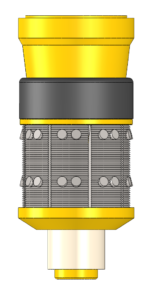

Thunder™ Dissolvable Frac Plug

- Robust Elastomer

- Harsh Environments

- Full degradation

The Recedó Thunder™ Dissolvable frac plug is engineered for excellence in hydraulic fracturing operations, specifically addressing the need for reliable sealing and efficient cleanout. Constructed from a robust degradable elastomer, this plug ensures a tight seal during the fracturing process, allowing for optimal pressure maintenance and effective fluid management. The quick degradation of the material post-operation significantly enhances the cleanout process, reducing downtime and facilitating a smoother transition to subsequent production phases.

One of the most remarkable aspects of the Recedó Thunder™ plug is its high degree of customizability. Recognizing that each well presents unique challenges, the plug can be tailored to meet the specific requirements of your application. Whether you are dealing with varying pressure conditions, different types of fracturing fluids, or distinct wellbore characteristics, the Recedó Thunder™ plug is adaptable to your needs. This level of versatility not only maximizes the efficentcy of your frac operations but also helps mitigate potential risks associated with unexpected wellbore conditions.

In addition to its customizable features, the design of the Recedó Thunder™ plug promotes enhanced performance in complex environments. The robust elastomer material is engineered to withstand the demanding conditions typical in unconventional reservoirs, ensuring reliable operation throughout the fracturing process. The ability to maintain a tight seal under pressure is critical for achieving the desired fracturing results, and the Recedó Thunder™ plug excels in this area.

Furthermore, the quick degradation of the plug after the completion of frac operations translates into significant operational efficiencies. As the plug dissolves in the presence of wellbore fluids, it eliminates the need for retrieval equipment and additional interventions, streamlining the workflow and reducing associated costs. This not only enhances productivity but also minimizes the environmental impact by reducing the need for mechanical removal processes.

In summary, the Recedó Thunder™ Dissolvable frac plug is a cutting-edge solution for operators seeking to optimize their hydraulic fracturing operations. With its robust design, customizable features, and efficient cleanout capabilities, it stands out as an essential tool for navigating the complexities of modern wellbore challenges.

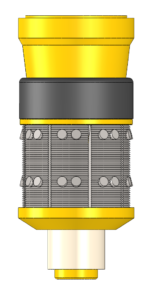

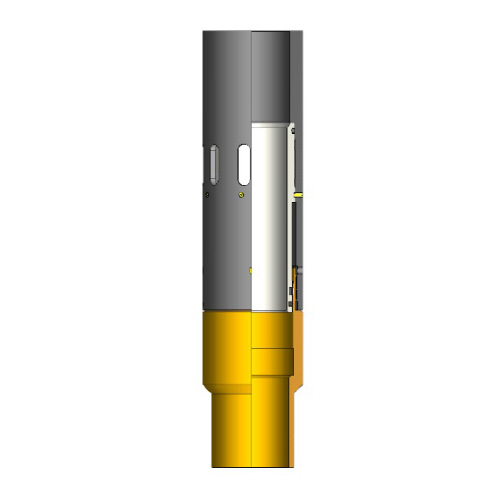

Twister™ Dissolvable Frac Plug

- Extended Range

- Custom Chemistry

- Maximum Control

The Recedó Twister™ Dissolvable frac plug is an innovative solution designed to effectively address the challenges posed by unforeseen wellbore restrictions during hydraulic fracturing operations. As operators encounter unexpected obstacles, such as irregularities in the wellbore or variations in formation, having a reliable and adaptable tool becomes crucial for maintaining operational efficiency and achieving desired outcomes.

One of the standout features of the Recedó Twister™ plug is its high degree of customizability. Each plug can be tailored to meet the specific requirements of your application, whether it involves varying pressure conditions, fluid types, or wellbore characteristics. This versatility ensures that you can optimize your frac operations to achieve the best possible results, regardless of the complexities you may face in the field.

Furthermore, the dissolvable nature of the Recedó Twister™ plug adds significant advantages. Once the hydraulic fracturing process is completed, the plug seamlessly dissolves in the presence of wellbore fluids, eliminating the need for additional retrieval operations or interventions. This not only reduces costs associated with plug removal but also minimizes the risk of further complications that can arise from traditional mechanical plugs.

Additionally, the design of the Recedó Twister™ plug promotes enhanced flow efficiency and minimizes pressure loss during frac operations, contributing to improved overall production rates. With its robust construction and reliable performance, this frac plug is engineered to withstand the demanding conditions often encountered in unconventional reservoirs.

In summary, the Recedó Twister™ Dissolvable frac plug stands out as a superior choice for operators looking to navigate the complexities of wellbore restrictions while maximizing the effectiveness of their hydraulic fracturing efforts. With its customizable options and dissolvable technology, it represents a significant advancement in frac plug design, ultimately leading to better operational outcomes and enhanced productivity.

Recedó™ Extended Reach Frac Plugs

- Extended Range

- Custom Chemistry

- Maximum Control

Dissolvable plugs built to perform in the most demanding extended-reach laterals. Each plug in the Recedó™ extended reach series is engineered for smooth deployment, reliable isolation, and full dissolution in long, tortuous wellbores where conventional plugs fall short.

Twister™ Dissolvable Frac Plug

The Recedó Twister™ Dissolvable frac plug is an innovative solution designed to effectively address the challenges posed by unforeseen wellbore restrictions during hydraulic fracturing operations. As operators encounter unexpected obstacles, such as irregularities in the wellbore or variations in formation, having a reliable and adaptable tool becomes crucial for maintaining operational efficiency and achieving desired outcomes.

One of the standout features of the Recedó Twister™ plug is its high degree of customizability. Each plug can be tailored to meet the specific requirements of your application, whether it involves varying pressure conditions, fluid types, or wellbore characteristics. This versatility ensures that you can optimize your frac operations to achieve the best possible results, regardless of the complexities you may face in the field.

Furthermore, the dissolvable nature of the Recedó Twister™ plug adds significant advantages. Once the hydraulic fracturing process is completed, the plug seamlessly dissolves in the presence of wellbore fluids, eliminating the need for additional retrieval operations or interventions. This not only reduces costs associated with plug removal but also minimizes the risk of further complications that can arise from traditional mechanical plugs.

Additionally, the design of the Recedó Twister™ plug promotes enhanced flow efficiency and minimizes pressure loss during frac operations, contributing to improved overall production rates. With its robust construction and reliable performance, this frac plug is engineered to withstand the demanding conditions often encountered in unconventional reservoirs.

In summary, the Recedó Twister™ Dissolvable frac plug stands out as a superior choice for operators looking to navigate the complexities of wellbore restrictions while maximizing the effectiveness of their hydraulic fracturing efforts. With its customizable options and dissolvable technology, it represents a significant advancement in frac plug design, ultimately leading to better operational outcomes and enhanced productivity.

Recedó™ Composite Frac Plugs

Built for drill-out speed and predictable performance — the HurricaneТМ Composite is our workhorse frac plug designed for reliable stage isolation and efficient millout. Featuring a full composite body with a short overall length, the Hurricane excels in high-pump-rate environments and minimizes debris for faster returns to production. Engineered for versatility and run-rate reliability, it’s a top choice for plug-and-perf operations across U.S. shale plays.

Hurricane™ Composite Frac Plug

- Short-length design for reduced completion time

- Full composite construction enables clean millout

- Pressure-rated and field-proven across multiple basins

- Ideal for operators seeking cost-effective composite plug performance

The Hurricane™ Composite Frac Plug is engineered to deliver a robust and reliable solution for hydraulic fracturing operations. Constructed entirely from composite materials, this frac plug has been rigorously tested and proven effective in various basins across the USA, demonstrating its reliability in diverse conditions and environments.

One of the key advantages of the Hurricane™ plug is its lightweight yet strong construction, which facilitates ease of handling and installation while maintaining the durability required to withstand the pressures encountered during fracturing. This makes the Hurricane™ plug an ideal choice for operators seeking both performance and efficiency in their frac operations.

We offer a comprehensive range of sizes to accommodate different wellbore requirements, ensuring that you can find the right fit for your specific application. Our inventory is ready for immediate shipping, allowing you to quickly receive the products you need to keep your operations on schedule.

Recedó™ Bridge Plugs

Temporary or permanent — true zonal control.

Frontier bridge plugs provide dependable isolation for a range of downhole operations. Whether you need a composite plug that drills out easily or a cast iron plug for robust, long-term isolation, we have you covered.

Hurricane™ Composite Bridge Plug

- Composite construction with field-proven reliability

- Designed for drillable isolation in completion or intervention operations

- Ideal for zonal abandonment, casing tests, and temporary blocking

The Hurricane™ Composite Bridge Plug marks a significant advancement in the field of composite bridge plugs, setting a new standard in the industry. Designed to meet the rigorous demands of today’s hydraulic fracturing operations, this plug stands out as one of the few fully composite options available that can confidently hold up to 10,000 psi both on the top and bottom. This impressive pressure capacity provides a substantial advantage during operations, particularly when it comes to cleanouts, ensuring that the plug maintains integrity under challenging conditions.

The Hurricane™ Bridge Plug has undergone extensive testing and has proven its effectiveness in various basins across the USA. This rigorous validation process highlights its reliability in diverse environments, making it a trusted choice for operators facing varying operational challenges. Whether in high-pressure settings or complex geological formations, the Hurricane™ plug is engineered to perform consistently, delivering peace of mind to those deploying it in the field.

In addition to its robust design and high-pressure capabilities, the Hurricane™ Composite Bridge Plug is also lightweight, allowing for easier handling and installation. This feature significantly enhances operational efficiency, enabling quicker deployment and retrieval processes, which is crucial in fast-paced fracturing environments.

Operators can take advantage of the Hurricane™ plug’s advanced features to improve overall workflow and reduce downtime associated with traditional bridge plugs. With its proven track record and commitment to reliability, the Hurricane™ Composite Bridge Plug is an essential tool for those looking to optimize their hydraulic fracturing operations.

Tsunami™ Cast Iron Bridge Plug

- Rugged, high-strength cast iron body

- Tubing-set or wireline-deployed options

- Suited for permanent isolation or abandonment applications

- Built to withstand differential pressures in demanding downhole conditions

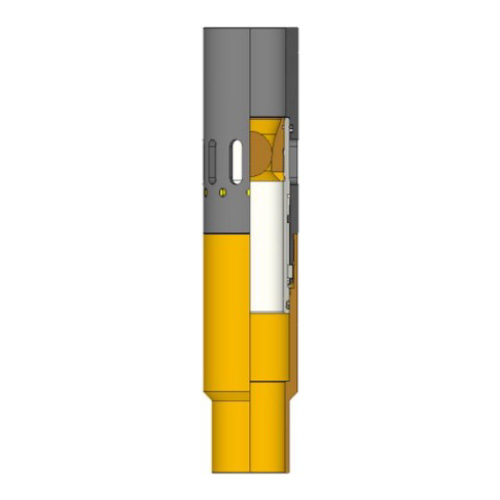

The Tsunami™ Series is a cutting-edge line of advanced bridge plugs meticulously engineered to provide secure wellbore isolation in a variety of challenging environments. These bridge plugs boast a unique design that facilitates an easy transition between wireline and hydraulic setting methods, significantly reducing the overall inventory requirements for operators. This adaptability not only streamlines operations but also enhances logistical efficiency, allowing for a more flexible approach to wellbore management.

One of the standout features of the Tsunami™ Series is its drillable bridge plugs, which are compactly designed for seamless drill-out operations. This means that once the intended purpose of the bridge plug is fulfilled, it can be efficiently removed without extensive delays or complications. The incorporation of a one-piece packing element along with ratchet lock rings ensures superior sealing performance and exceptional durability, even in high tensile casings. This design consideration is crucial for maintaining well integrity and preventing any potential leaks throughout the operational lifecycle.

The Tsunami™ Series builds upon the proven success of the TB series 2-in-1 setup, taking compatibility and versatility to new heights. All wireline setting sleeves from our SWR Cement Retainer line can be utilized to set the Tsunami™ line, ensuring that operators can easily integrate these advanced plugs into their existing workflows without the need for additional equipment.

Versatility is further highlighted in the various setting methods available for the Tsunami™ Series. Operators can choose between wireline or hydraulic methods, as well as ported or solid adapters, providing the flexibility needed to address specific operational demands. The design also allows for quick and easy swapping of elements by simply removing the bottom set-screwed components while keeping the top end intact. This feature not only saves time during deployment and retrieval but also enhances the overall efficiency of the operation.

In summary, the Tsunami™ Series represents a significant advancement in bridge plug technology, prioritizing versatility, compatibility, and operational efficiency. With its innovative design and robust construction, it stands out as a top choice for operators seeking reliable and effective wellbore isolation solutions. Trust the Tsunami™ Series for your bridge plug needs, and experience the benefits of enhanced operational capabilities and streamlined processes.

If you have any questions or would like to explore how the Recedó Series can specifically benefit your operations, please feel free to reach out to our sales team at sales@frontieroiltools.com!

Drop Ball Frac Sleeve

The Ball-Open Frac Valve is actuated by a corresponding ball to seat combination. Once a ball is dropped and pumped down onto a seat, hydraulic differential pressure causes the inner sleeve to shift down into the open position, Communication with the annulus is now established and the breakdown of the formation creates a flow path which allows the fracturing treatment of that zone to begin. Each zone led into the well bore is incrementally progressive from the toe to the heel.

Immediate Open Toe Sleeve

The Immediate Open Hole Toe Valve eliminates the need for Tubing Conveyed Perforating (TCP) Toe Prep by providing a simple and reliable hydraulically actuated injection path. The Immediate Open Toe Valve can be pressure tested multiple times below the activation pressure.

Multi Test Toe Sleeve

The Multi Test Toe Valve eliminates the need for Tubing Conveyed Perforating (TCP) Toe Prep by providing a simple and reliable hydraulically actuated injection path. The Multi Test Toe Valve allows the Toe Valve to be opened without exceeding the desired test pressure and unlimited hold period. The Multi Test Toe Valve can also be pressure tested multiple times below the activation pressure.

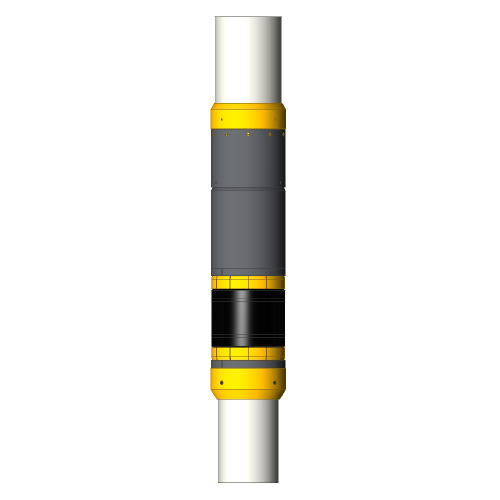

Open Hole Swell Packer

The Swell Packer is a downhole device used in Cemented and Un-Cemented Multi-Stage Liner Completions for Zonal Isolation. The Packer uses Specifically Formulated Elastomer to suit the Well Conditions to Swell in Water or Oil Based Fluids. A Seal is then created inside the open hole, typically straddling Ball Activated Frac Sleeve and Isolating the Open Hole Interval for Selective Fracturing.

Hydro Mechanical Open Hole Packer

The Open Hole Packer is a downhole device used in Multi-Stage fracturing operations for zonal isolation. This hydraulic set packer is specifically designed to set and seal in the open hole straddling a ball open frac. sleeve, isolating the open hole intervals into fracturing stages. The Open Hole Packer is equipped with an internal locking mechanism which ensures a positive and reliable long term set.